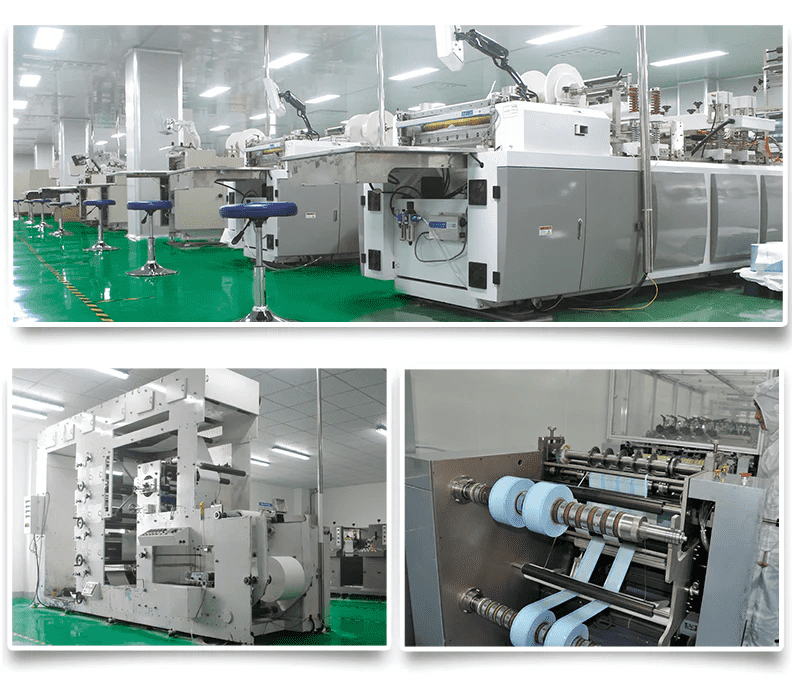

Micro semi-automatic POCT products is transforming the landscape of diagnostic testing. Traditional luminescent reagents often rely on cold-chain transport, limiting their international reach. However, Poclight's innovative lyophilized spherical reagents can be stored at room temperature (2-30°C) with a shelf life of over 18 months, completely eliminating cold-chain requirements. This advancement not only enhances accessibility but also maintains the high precision levels expected from chemiluminescent assays.

Poclight's mini semi-automatic POCT device is designed for efficiency, with dimensions comparable to an A4 sheet and a weight of just 6 kg. This compact design ensures that healthcare providers can easily integrate the device into various clinical settings. With a testing speed of 120T/h and support for multi-project mixed sampling, it caters to diverse diagnostic needs without compromising performance.

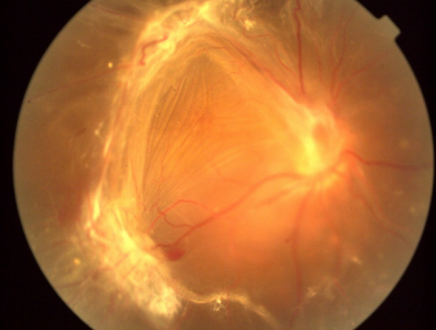

One of the key features of Poclight's product is its use of homogeneous chemiluminescence technology, which guarantees high sensitivity and specificity for accurate testing. This precision is crucial for effective diagnosis and treatment, enabling healthcare professionals to deliver quality care to patients.

Additionally, single-use lyophilized reagents further simplify the testing process. The "foolproof" operation allows users to complete tests with just one sample addition, streamlining workflows and minimizing errors. This ease of use makes it particularly suitable for grassroots medical institutions, where resources may be limited.

Speed is another significant advantage, with results available in as little as 3 minutes. This rapid turnaround time empowers healthcare providers to make informed decisions quickly, ultimately improving patient outcomes. Moreover, Poclight's device offers a cost-effective solution, making it accessible for a wider range of healthcare facilities.

Micro Dry Honogeneous Chemiluminescence Immunoassay Analyzer and innovative lyophilized reagents represent a significant leap forward in diagnostic testing. With their compact design, rapid results, and simplified operation, they are well-positioned to meet the evolving needs of modern healthcare, paving the way for better patient care and broader accessibility.